Tomato season is short. In California’s Central Valley, canners have about seventy days to harvest and pack the entire season’s crop. Most people don’t realize that pizzerias all over the planet use canned tomatoes rather than fresh. Think about it; tomato season is short, so the “fresh” tomatoes you buy in March are far from what you’ll get coming off the vine in August. What’s wrong with off-season tomatoes? First of all, flavor is never the concern when breeding tomatoes. They’re grown to be tough enough to handle the rigors of the road. Secondly, they’re often grown in water (Canada) or in sand (Florida), so vital nutrients have to be added artificially. The industrial practices in the fresh tomato industry are also pretty bad, but you’ll have to read a book like Barry Estabrook’s Tomatoland for the full scoop on that.

The canned tomato doesn’t get its due, so I decided to take a quick trip out to Modesto, Ca for a first-hand look at how some of our favorite pizza tomatoes are grown, harvested and canned. I visited farms and facilities used by Stanislaus Food Products, one of the country’s leading tomato companies and certainly the most popular in the New York area. I personally love their products, which often take top honors at our annual tomato tastings (see here, here and here).

First we headed out to a farm that was in the midst of being harvested. Farmers in Modesto use amazing machines that harvest an entire vine in one shot. Check out this video for a better look at the machine. It has three sets of “eyes” that discard tomatoes that aren’t the correct color. The machines look for a bright red – you know TOMATO COLOR!

Here I am riding on the harvester. Can you tell I’m having the time of my life?

Next we learned about how the farm manager selects fields for harvest. It’s a tough job because you only get one shot. The big canisters behind us in this next photo are being filled with tomatoes after the harvester screens out the imperfect fruits. They have six hours to be canned, otherwise Stanislaus doesn’t use them. We were told the average time between vine and can for this company is actually 4.5 hours. Stanislaus only contracts farms that are within two hours of their cannery in Modesto.

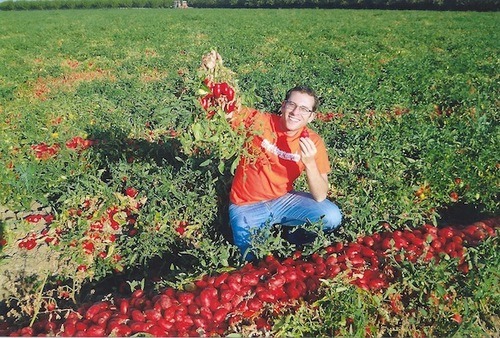

Here’s the farm manager, Justin, describing the process to us as I eat a tomato from the field. It does not get any more fresh!

After the field, we drove a few minutes to the cannery. It’s an incredible operation but we weren’t allowed to take photos so I’ll just have to describe it from memory. When fruits come in, they are first washed and tested for quality before being paired up with other batches in order to create a perfectly balanced flavor blend.

Tomatoes then get loaded onto a conveyor belt where they travel through a series of stages. I was amazed to see so many human hands involved with the process. Several sets of people manually remove imperfect tomatoes from the line, letting only the best go through. There are also several scientific test points. Believe be, I wanted to take pictures of all of them because they were SOOOO AWESOME!!! One test involved pouring a cup of crushed tomato onto a slope to test its viscosity. There were even biochemists on hand – not because of any state law, just because the company wants to keep high standards. It was amazing.

Stanislaus invites pizzerias to come visit their operation and experience tours like the one they did for me. It’s not a direct sales pitch, just a way of educating their consumer base. Once you witness the process, it’s not a mystery that this company is held in such high regard within the pizza community.

BONUS PHOTO: I also got to check out an olive orchard just up the road…