I got a phone call from “Papa” John Schnatter yesterday. He wanted to thank me for accepting his invitation to visit his corporate headquarters last week. Mind you, I have never been a Papa John’s fan. I’ve had it twice in my life – once while visiting a friend at college and the other as part of a TEAM SPT mission to compare the big chain pizza companies. It’s not something I’d ever choose to eat, but Papa John’s is a huge force in the global pizza scene so it’s my duty to understand their operation.

Papa and his PR team summoned about a dozen food bloggers to Louisville, KY for a behind-the-scenes tour of their headquarters and commissary. For the other attendees, this was a golden ticket to Willy Wonka’s factory. I was the only real skeptic of the group, which I only assume was an intentional move by the PR firm that set up the visit. I’m an advocate for mom and pop pizzerias, so companies like Pizza Hut and Domino’s are the enemy. Still, I was delighted to accept the invitation. After all, I’m super interested in the workings of any pizzeria operation because it helps me gain a stronger understanding of the entire business.

John Schnatter met us in the lobby of his headquarters. It’s a mini-museum of his company’s history complete with original signs, articles, and pizzeria equipment. He even has the famous Camaro on display, which he sold in order to afford the equipment he needed to start making pizzas in the broom closet of his father’s bar (it’s not the actual Camaro, just a replica). I’m sure it’s a true story, but the emphasis on this story only drove home the nature of our visit: to perpetuate the company message through impartial, informal media streams. Fair enough, I certainly wasn’t about to complain.

We moved on to the commissary, which was pretty much what I expected: flour cascaded from a giant hopper into an epic mixer, where it combined with the usual suspects before continuing the automated journey through various chutes and conveyor belts before heading to the proofing room. Think Edward Scissorhands. Companies like Domino’s and Papa John’s work on a commissary system in order to standardize their product. They have ten commissaries around the country that make dough and prep sauce and cheese for purchase by store managers.

It’s always fun to see this side of a food business because of the mechanization of the process. These are really large quantities and it’s amazing how much precision is required to make it work. But the tour got way more interesting as we progressed through the office building. I almost lost the group when we briefly met PJ’s in-house designers. These are the folks responsible for PJ’s strong pizza box game and I had to express my appreciation for their work. As it turned out, they all knew about my collection and pizza box book!

My favorite part of the tour was seeing the testing lab, which PJ’s uses to make sure the products they’re purchasing are in line with the company’s specifications. The tomato should fit within a predetermined dissolved sugar content and pH. Even the pizza boxes are tested to make sure the ink adhered to them instead of rubbing off onto the customer’s hands. And who does’t love a good lab?!?!?

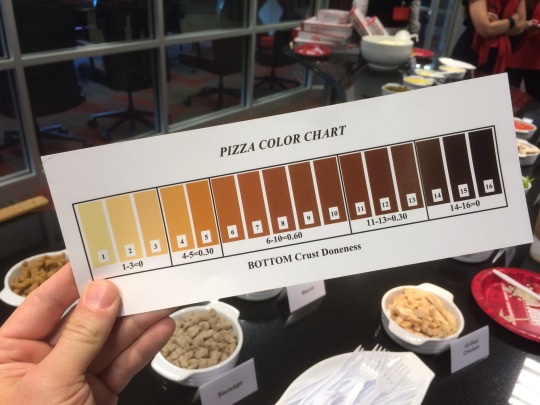

I have to share some of the tools PJ’s uses to control the quality of their product. This chart indicates target color for the top crust of their pizza.

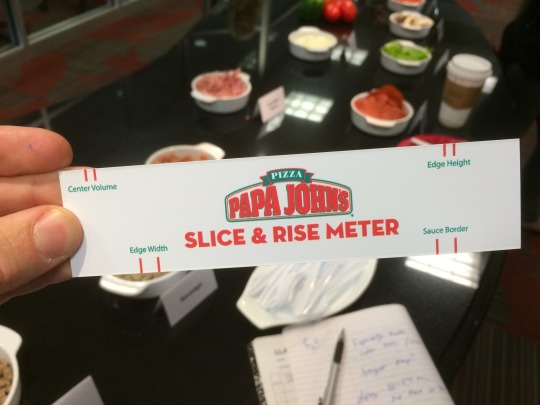

There’s another chart for bottom crust and also a guide for crust thickness and sauce exposure. I love that these exist.

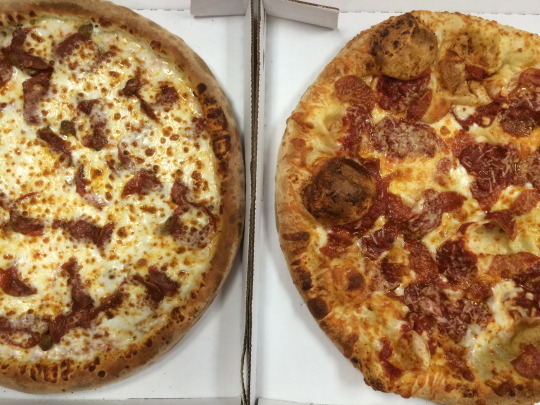

Finally, we headed into the test kitchen for the grand finale of our day with John. Everyone was invited to assemble their own pizza with doughs stretched by David, the guy who makes all the pizzas for Papa John’s commercials. It was super interesting to talk to him about all the rules and regulations for making a PJ’s pizza. When it came turn for me to make my pie, my third ever Papa John’s pizza, I went off the edge and violated all the rules. Instead of docking my dough (degassing it with a spikey roller gadget), I left the dough alone. Instead of finishing the pie with mozzarella (they call it “cheese lock,” I started with it. Instead of an even layer of tomato sauce I dotted it on top. Here she is pre oven.

And now post oven, next to one of Davis’s perfect Papa John’s specimens. Notice how bubbly and blistery mine is. I would have scored extremely low on Papa’s scale, but when John saw it his exact comment was “That’s badass!” Then he ate a slice. It was pretty weird.

There are a couple things I should say about Papa John’s:

1. Papa John’s is a pizza company. They don’t do pasta. They don’t do sandwiches, they don’t do salads. Just pizza. Other pizza chains have diversified their menu but Papa John’s has stuck with pizza.

2. John is not just a figurehead, he really runs the company and seems to be a common fixture around the office. Nobody was phased to see him there. And he is very passionate when talking about the company’s goals and methods.

3. Schnatter’s current pet project involves “cleaning up the label.” They’re spending a ton of money pulling preservatives and other nasty chemicals out of their products. It’s pretty serious, he’s trying to reach Chipotle status with regard to ingredient purity. This project may have been the main objective of bringing us in, since all the other bloggers are into health and wellness. Maybe he wanted us to get the word out as a way of softly opening the marketing stream. I think it’s great that they’re cleaning things up and I’d love to see others follow.

I’m glad I went to Louisville for this deep study on what makes Papa John’s tick. I’m way more equipped to answer questions about chain pizza companies when they come up on pizza tours. John was a great host and his staff was extremely helpful in answering all of my questions. I can’t say I’ve been converted into a customer, but I definitely have a stronger handle on what PJ’s business is all about.